![]()

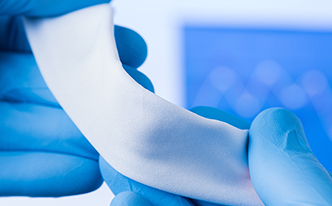

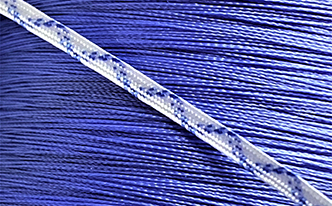

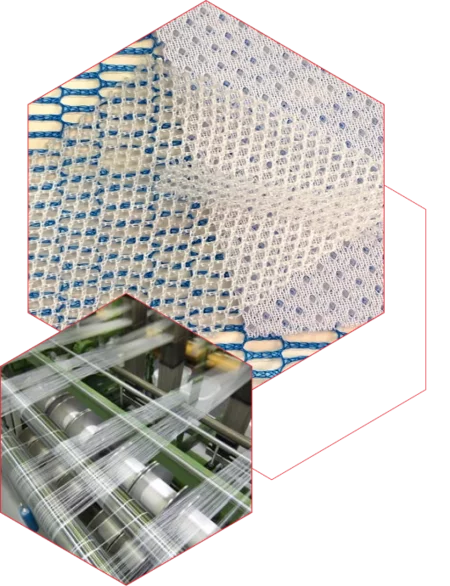

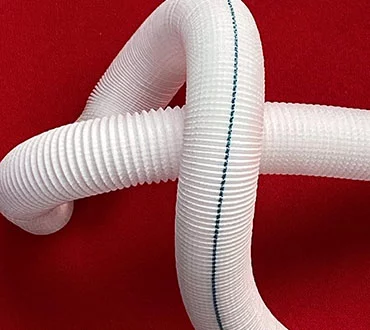

Textile Construction

Knitting, Weaving, Braiding and Non-Woven Technology

ATEX Technologies has been transforming fiber science capabilities for over 20 years. We employ several manufacturing technologies that have been optimized to provide very unique and highly specialized products that drive the fit, form and function of your medical component. These techniques include weaving, knitting, braiding and non-woven processes. All components engineered at ATEX start with one or more of these core competencies; and the choice of which to use is highly dependent upon the characteristics required for the component, and end device, to perform as it should. In addition, ATEX offers numerous ways to add additional features to your component through fabrication. These enhancements include fabric marking and dying, precision laser cutting, custom coatings, heat forming, sewing and assembly. You can find out more about our capabilities in fabrication here. ATEX’ commitment to quality and operational excellence will ensure that your product is manufactured with the greatest attention to detail from the beginning of its development process all the way to large scale manufacturing. Do you need a fabric with an open pore structure? A thin fabric with little give? A soft structure that will compress until deployed? We’ve got you covered.

Choosing the Right Textile Technology:

Component Construction and product performance go hand in hand.

Similar Shapes can be made using different techniques.

We engineer components for manufacturability from the start.

Available Textile Types

![]()

Let's partner and innovate together

Have questions? Ready to get started? ATEX

is available to discuss the scope of your

component needs.